Vapour Degreasing Cleaner using solvents

There are many solutions for degreasing workpieces. In the past, use was often made of trichlorethylene, fluorinated hydrocarbons and Isopropyl alcohol (IPA). However, these liquids involve many environmental and safety hazards. Degreasing in water-based systems is a worthy alternative. However, the operational costs of these types of machines are relatively high. Not only heating the liquids for cleaning and rinsing, but also drying with hot air causes a high electricity consumption. For good results it is important that you change the liquids regularly. Costs due to the high water consumption and the processing of the waste water add up quickly. Affordable degreasing in a sustainable and efficient way is possible with modern solvents in a vapor degreaser.

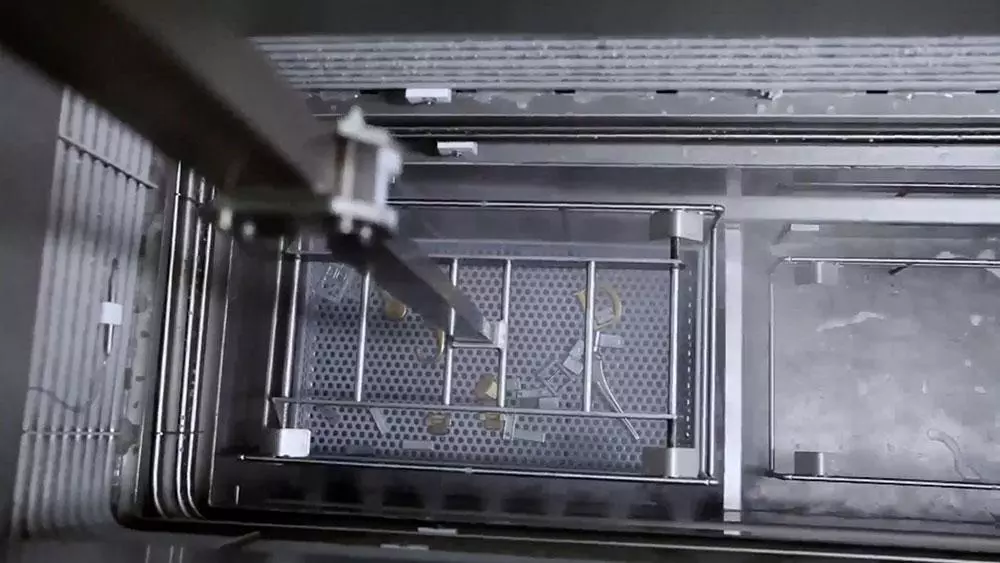

Fast and powerful degreasing with safe means for people and the environment, that is possible with the range of solvent cleaners that Kemet offer. The dimensions vary from handy and mobile (approx. 622 x 870 x 1050 mm) to a compact machine (approx. 2000 x 1000 x 3000 mm).

Developments in chemistry make thorough cleaning possible. At the same time, ozone depletion and fire hazard are excluded. The low GWP and toxicity make these solvents very easy to use.

Despite the compact footprint of a vapor degreaser, the cleaning process consists of several essential phases to achieve a perfect result. You bring the solvent to the boiling point (often 40 - 45 ° C). In a first phase, the solvent vapours condense on the workpiece surface. Much of the contamination flows with the solvent from the workpiece and ends up in the cooking tank. After this pre-cleaning, the part is placed in a second tank. The immersion in the clean solvent and the ultrasonic agitation thoroughly clean the workpiece, even in hard-to-reach places. Then, by reinserting the part into the distilled solvent vapor zone, the vapor purge removes any residual oil or grease residue. Cooling coils above the vapor phase condense the solvent so that it flows back into the machine. The liquid is thus continuously distilled and reused.

Thanks to the low temperature of the entire process, you degrease thermally sensitive workpieces without risk. The drying process is so fast that a capacity of 10 batches per hour is no exception. Thanks to the low surface tension, you can easily clean small bulk goods or workpieces with complex geometries.

Benefits

- Super fast, cycle time of about 5 to 6 minutes;

- Hand warm, clean and dry end result;

- Based on non-flammable solvents;

- No risk of corrosion, because no water is used;

- Low energy consumption, less than half of traditional heated systems;

- Small footprint, takes up little space;

- Environmentally friendly;

- Optionally manually or fully automated;

- Nice touchscreen for programming the cycle.

Applications

- Removal of fats, oils, inks, polishing and lapping pastes;

- Degreasing for control in the measuring room;

- Degreasing of small mould inserts;

- Cleaning of precision mechanical parts;

- NOT SUITABLE for the removal of water based pollution.