Vickers & Knoop Hardness Testers

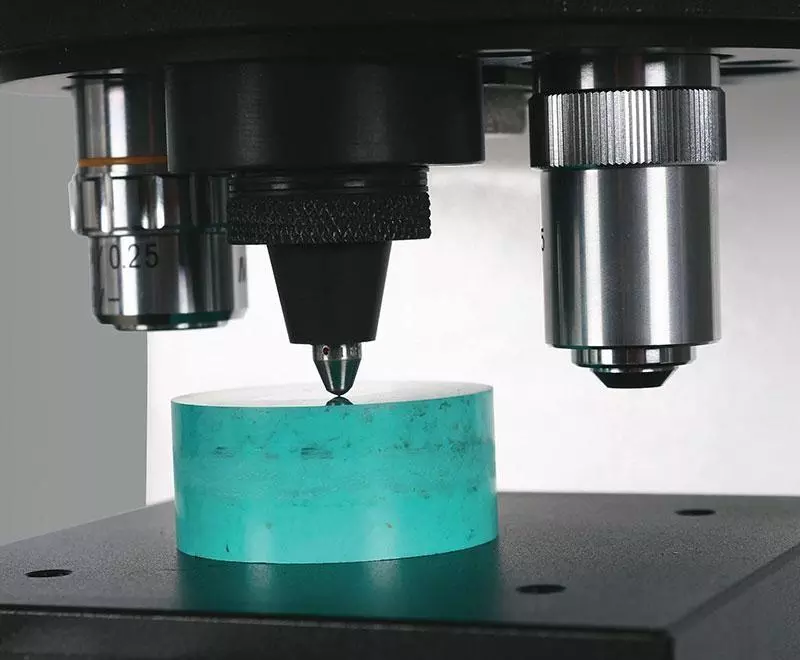

DUROLINE M Series are ideal instruments for quality assurance, quality control, research and metallurgical departments to monitor the hardness during fabrication and after heat treatment or welding as well as for the performance analysis on metal parts and new alloys. Typical applications are determining the Vickers microhardness of small precision parts, thin material or wire, coatings and performing case depth determinations (CHD, EHT, NHT) on cross sections, both manually or automatic on this advanced hardness tester system.

Recently developed by an international multi-disciplinary team with a wide hardness testing experience, the DUROLINE M-Series are based on the latest technology available, focused on fast cycle time with high reproduceable accuracy within international standards. The system features a smart and very service-friendly synergy of a robust and proven mechanical construction and integrated electronics system control featured by a fast CANBUS technology and a high-quality Windows based mini-pc. Monitoring the hardness testing process significantly improved by using modern user interfacing technology such as 10-point multi-touch screen operation supported by a fast & secure display connection. Combined with top quality components and a high performance mini-pc, this system guarantees customers a solid and accurate performance over many years to come. In this way, the DUROLINE M Micro-Vickers hardness tester offers a highly functional and reliable automated indentation test & measurement system.

Complete micro-load range for HV/HK scales from 10gf to 1kgf

By selecting between 8 loads steps for microhardness testing in Vickers or Knoop, any specimen can be tested and measured within the applicable standards. Fast and easy setting of loads by a conventional manual knob.

Magnification range

Combining the excellent performance of the digital camera, LED illumination and software with a series of available objectives, the DUROLINE M Series provide correct measurement under any test load within the international standards.

High precision spindle with motorized option

For accurate microhardness testing and fast auto-focusing, the elevating speed and backlash of the spindle are critical. By using quality components and design experience, the DUROLINE M Series spindles guarantee long life without loss of accuracy due to wear and friction, even for automated Z-axis systems.

'N-Sure' Test and Measurement Software

The N-Sure software program features a flexible Windows based user interface that increases productivity and operator efficiency by automating the test & measurement process and optional motor-stage navigation process. Since the application and removal of the test loads and measurement are fully automatic, repeatability is excellent, testing time is reduced and throughput is increased. As a result, costly and time-consuming rework is eliminated.

Fully Automatic Test and Measurement

DUROLINE M4 is equipped with a high precision motorized XY-stage with 100x150 mm travel range and Autostage software module. It provides multiple tests & measurements fully automatically without operator intervention.

Case Hardening Depth (CHD) Testing

Case Hardening Depth Module is optionally available for all DUROLINE M models. For DUROLINE M1 and M2 models, Case Hardening Depth testing is done manually by digital manual XY-Stage. For DUROLINE M4, Case Hardening Depth testing is done automatically by motorized XY-Stage.

Scanning Overview Image Feature

Mapping function allows overview image of complete sample surface. The test points are easily determined on the sample with pre-defined or user defined patterns.

Automatic Focus

(Available on M2 and M4 models) DUROLINE M2 and M4 models are equipped with high precision motorized spindle and Autofocus software module. It automatically sharpens the image in seconds. This provides extra convenience, maximum automation and time saving.

Motorized XY-Stage

(Available on M4 model) DUROLINE M4 is equipped with high precision motorized XY-stage with 100x150 mm travel range and Autostage software module. It provides multiple tests & measurements fully automatically without operator intervention. Mapping function allows overview image of comple sample surface. The test points are easily determined on the sample with pre-defined or user defined patterns.

Automatic Light Brightness

The light brightness is automatically adjusted by the user interface software for the best image quality and the most accurate auto measurements. The hardness tester equipped with powerful LED light source and compact optic system to provide excellent image quality.

| DUROLINE M1 | DUROLINE M2 | DUROLINE M4 | ||

|---|---|---|---|---|

| Hardness Scales | Vickers HV as per ISO 6507, ASTM E384, E92 | HV0,01 - HV0,025 - HV0,05 - HV0,1- HV0,2 - HV0,3 - HV0,5 - HV1 | ||

| Knoop HK as per ISO 4545, ASTM E384, E92 | HK0,01 - HK0,025 - HK0,05 - HK0,1- HK0,2 - HK0,3 - HK0,5 - HK1 | |||

| Hardness conversions to other scales | As per ISO 18265 | |||

| Test Loads | Test Loads (gf) | 10gf – 25gf – 50gf – 100gf – 200gf - 300gf- 500gf - 1000gf | ||

| Test Loads (N) | 0,09807N - 0,2452N - 0,4904N - 0,9807N - 1,961N - 2,942N - 4,904N - 9,807N | |||

| Test Load Accuracy | "10gf - 200gf: +/- 1,5% and > 200gf: +/- 1,0% As per ISO standard (and ASTM E-384, JIS B7725, JIS B7734)" | |||

| Test Load Dwell Time | "from 5 - 99 sec with 1 sec increments As per ISO standard (and ASTM E-384, JIS B7725, JIS B7734)" | |||

| Test Load Application Speed | "10gf - 200gf: < 0.070 mm/s and > 200gf: < 0.200 mm/s As per ISO standard (and ASTM E-384, JIS B7725, JIS B7734)" | |||

| Load Force Application | Dead-weight, Automatic motorized, load, dwell, unload | |||

| Load Selection | Manual by external setting knob | |||

| Turret | Turret Configuration | Motorized 3-mount turret: 1 indenter, 2 objectives Position Auto-indication | ||

| Indenter | Including 1 Vickers Diamond Indenter (ISO/DaKKs certified, Made in Germany) | |||

| Objectives | "Standard objectives 10X, 40X, optional 5X, 20X (Made in Germany) Image capture by integrated CCD-camera (no eyepiece)" | |||

| Optic System | Sample Image Capture | By Integrated CCD Camera, 5.0 MP, USB 3.0 (Made in Germany) | ||

| Indent Measurement Resolution | 0,00002 mm (0.02 μm) | |||

| Illumination | Illumination Source | Built-in LED Light Source | ||

| Automatic Brightness Control | Standard for highest contrast and sharpnes | |||

| Spindle | Z-axis (Spindle Vertical Movement) | Manual | Motorized | Motorized |

| Auto-Focus AF | Not Available | Standard | Standard | |

| "Motorized XY-Stage" | Motorized XY-Stage (for Fully Automatic Multiple Test & Measurements) | Not Available | Not Available | Standard |

| Travel Distance | Not Available | Not Available | 100x150 mm | |

| Controller System | Controller | "Built-in Windows operated mini-PC, communicates the hardness tester electronics by CANBUS Protocol" | ||

| Interface Network | Interface network USB (x4), Displayport (x2), LAN (x1) and Wireless LAN | |||

| Auxilliary | Optional Keyboard, Mouse (wireless) | |||

| Monitor | "External 22” Full HD Capacitive 10-point Multi-Touch Desktop Monitor, IPS Panel, Antistatic Shield, Tiltable, Integrated Power Adaptor" | |||

| User Interface | Operating System | Windows 10 | ||

| Test Settings | Scale, Load Dwell Time , Start, Turret positioning, Hardness Conversion, Illumination, Screen preference settings, Alerts for errors | |||

| Measurement Settings | Surface Image capture, Indentation capture, Manual measurement and Auto-measurement, Single indents, Manual pattern, Preset pattern, CHD, EHT, NHT, GO/NG judgement, Statistics, Conversion, Cilindrical correction, Language, Database, Test Reports with image analysis data, Data export, User management, Service and Calibration Settings | |||

| Tester Body | Operational Environmental Conditions | "Ambient Operating Temperature Range: 23°C +/- 5°C Ambient Humidity Range: RH 40% to 70% relative humidity, non-condensing" | ||

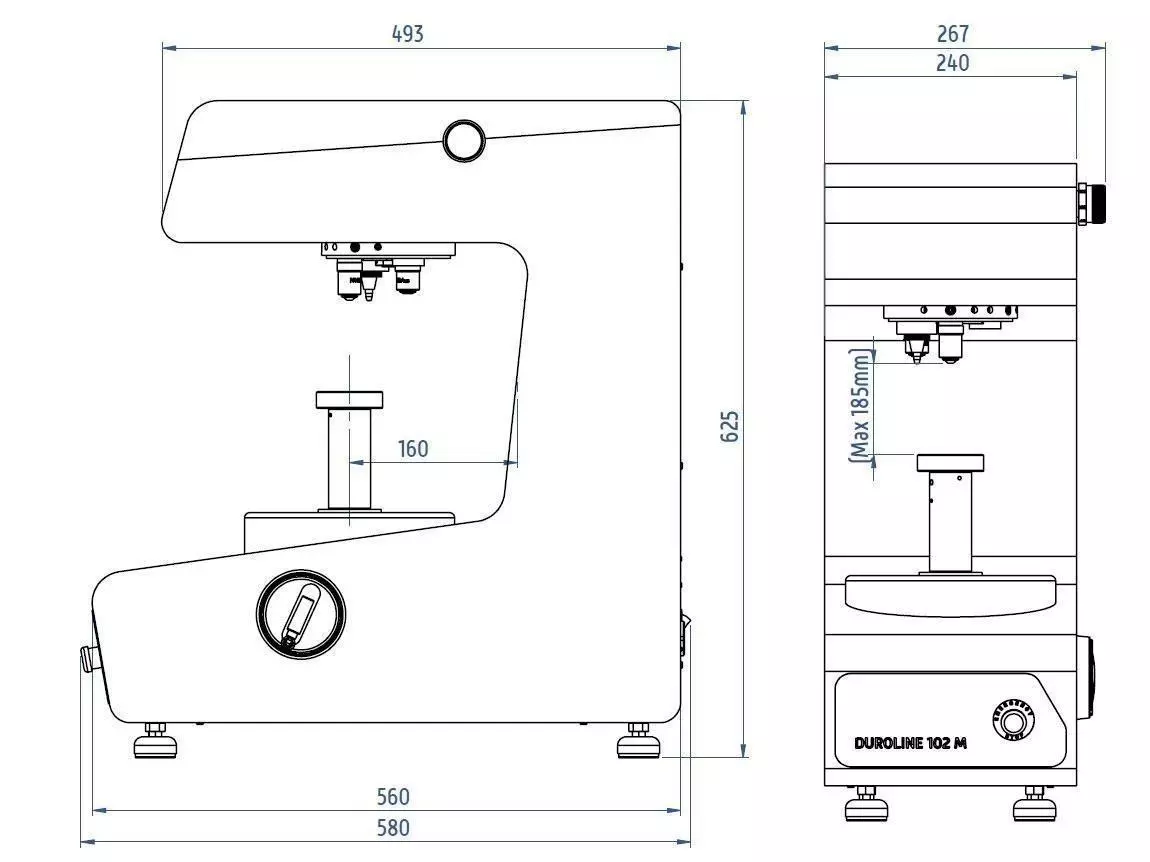

| Dimensions, WxDxH | 240x560x625 mm | |||

| Specimen Accommodation | Vertical 185 mm, Horizontal (throat depth) 160mm | |||

| Weight | 65 kgs | |||

| Mains | 100-240 V, 1-phase, 50/60 Hz, autosetting | |||

| Features | Automatic Test & Measurement | |||

| Automatic Light Brightness Control | ||||

| Motorized Z-Axis Spindle | ||||

| Automatic Focus | ||||

| Motorized XY-Stage | ||||

Accessories

Test stages

The DUROLINE M Series feature various stages and fixtures that fit any application. Starting with the basic manual XY-stage with either mechanical or digital micrometers, the hardness tester can also be equipped with a motorized stage to facilitate single or multi-sample holders. To fix various geometries of specimen that are not mounted, there are several clamping devices available to finish the job quick and precise.

Object Lenses

DUROLINE M equipped with 10x and 40x high quality German made object lenses for maximum image sharpness. 5x and 20x objectives are also optionally available for all kind of testing needs.

Test Blocks

ISO/DaKKS certificated German made test blocks are optionally available for Indirect verification of tester.

Indenters

ISO/DaKKS certificated German made Vickers and Knoop indenters are optionally available for most accurate and reliable testing.

Vickers/Knoop Indenters

GR 2047

GR 2048

Flat and V Anvils

GR 2021

GR 2022

Manual XY Stages

GR 2023

GR 2024

Fine Specimen Holders

GR 2026

GR 2027

GR 2028

Certificated Standard Test Blocks

GR 2061

...

GR 2069

Certificated Calibration Scale Glass

GR 2071

Object Lenses, 5X/10X/20X/40X

GR 2041

GR 2042

GR 2043

GR 2044

Precision Vise (Opening 43mm)

GR 2025

Software Module for EHD, CHD Testing

GR 2081

Specimen Holder for Mounted Samples Ø25/ 30/40/50 mm

GR 2031

GR 2032

GR 2033

GR 2034

Multiple Specimen Holder for Multiple Mounted Samples Ø25/30/40 mm

GR 2035

GR 2036

GR 2037

Dimensions