Diamond Suspension

Diamond suspensions are used during the sample preparation stages for fast stock removal and to produce a perfect polished surface ready for analysis. The type of diamond suspension to use depends on the material being polished and the surface finish required. A few examples of processes specific to different materials are listed below. Generally Monocrystalline diamond will provide a good performance for most processes but in some cases Polycrystalline diamond suspension will be required. For example, polishing hard or sintered materials, Polycrystalline diamond offers outstanding stock removal and polishing performance.

Aquapol is the next generation of water based diamond suspensions for sample preparation. It is available in monocrystalline (Aquapol-M) and polycrystalline (Aquapol-P). Aquapol is easy to clean and non-foaming.

- Uniform suspension of diamond particles

- No agitation required

- Suitable for dispensing by Kemet Electronic Dispenser or alternative systems

- ZERO Volatile Organic Compounds (VOC*)

- Colour coded for easy identification

- Lubricating Fluid Type W9 recommended with AquaPol

Available in 400g bottles with trigger spray. Other sizes (500ml, 1 litre, 2.5 litres etc.) are available upon request.

We also offer low viscosity, high concentration, oil based suspensions available in monocrystalline (Type OM) and polycrystalline (Type OP).

Manufactured to ISO 9001:2015 Quality Assurance standards.

Aquapol-M diamond suspension

Water Based Monocrystalline Diamond suspension. ![]()

| Micron | 400g | 1 Litre |

|---|---|---|

| 1/10 (0.1) | 219471 | 219490 |

| 1/4 (0.25) | 219459 | 219491 |

| 1/2 (0.5) | 219457 | 219492 |

| 1 | 219450 | 219493 |

| 3 | 219440 | 219494 |

| 6 | 219448 | 219495 |

| 9 | 219442 | 219496 |

| 15 | 219444 | 219497 |

| 25 | 219446 | 219498 |

Aquapol-P diamond suspension

Water Based Polycrystalline diamond suspension. ![]()

| Micron | 400g | 1 Litre |

|---|---|---|

| 1/20 (0.05) | 219500 | - |

| 1/10 (0.1) | 219472 | 219484 |

| 1/4 (0.25) | 219461 | 219485 |

| 1/2 (0.5) | 219463 | 219486 |

| 1 | 219452 | 219487 |

| 3 | 219453 | 219488 |

| 6 | 219454 | 219482 |

| 9 | 219455 | 219483 |

| 15 | 219456 | 219489 |

Note to users of WM/WP suspensions – these are still available

Type OM diamond suspension

Oil Based Monocrystalline Diamond suspension. ![]()

| Micron | 400g |

|---|---|

| 1/10 (0.1) | 216321 |

| 1/4 (0.25) | 216323 |

| 1/2 (0.5) | 216322 |

| 1 | 216324 |

| 3 | 216326 |

| 6 | 216328 |

| 9 | 216329 |

| 15 | 216331 |

| 25 | 216332 |

| 45 | 216333 |

Type OP diamond suspension

Oil Based Polycrystalline diamond suspension. ![]()

| Micron | 400g |

|---|---|

| 1/10 (0.1) | 216341 |

| 1/4 (0.25) | 216342 |

| 1/2 (0.5) | 216343 |

| 1 | 216344 |

| 3 | 216346 |

| 6 | 216347 |

| 9 | 216349 |

| 15 | 216350 |

Which Diamond Suspensions to use?

Below are a few examples of the recommended diamond suspensions for use during the polishing stages of sample preparation. A lubricating fluid is required.

| Material | Abrasive | |

|---|---|---|

| Pre-Polishing | Final Polishing | |

| AISI 1040 (Carbon Steel) | 6µ Aquapol-P | 1µ Aquapol-P |

| AISI 4340 Low alloy steel | 3µ Aquapol-P | 1µ Aquapol-P |

| AISI M2 High Speed Tool Steel | 6µ Aquapol-M | 3µ Aquapol-M |

| AA8011 Aluminium Alloy | 3µ Aquapol-P | COL-K (NC) |

| Carbon Fibre | - | 1µ Aquapol-P |

| Material | Abrasive | |

|---|---|---|

| Pre-Polishing | Final Polishing | |

| Ceramic | - | 0.25µ Aquapol-P |

| Copper | 1µ Aquapol-P | COL-K (NC) |

| Glass | 3µ Aquapol-P | 0.25µ Aquapol-P |

| Mg-9Al (Magnesium Alloy) | 3µ Aquapol-P | COL-K (NC) |

| Titanium | 6µ Aquapol-P | COL-K (NC) |

EasyPol - Diamond & Lubricant in a Single Application

Easypol is a diamond suspension and lubricant combination, resulting in faster and simpler metallographic sample preparation. These suspensions result in high stock removal, allowing preparation time to be reduced. The diamond suspension / lubricant combination ensures that the optimum ratio of diamonds and lubricant is predetermined, resulting in a quality polishing operation, first time and every time.

- Lower cost of consumables

- Reduction in preparation time

- Excellent and reproducible results

- Easy to use

- Water based

- Easy to clean

- Can be used in automatic dosing systems

- Also available in 2.5 and 5 litres

| Micron | EasyPol (For routine metallographic sample preparation) | EasyPol+ (Special formula for reduced polishing times) | ||||

|---|---|---|---|---|---|---|

| 500ml | 2.5 Litres | 5 Litres | 500ml | 2.5 Litres | 5 Litres | |

| 1/4 | 250600 | - | - | - | - | - |

| 1 | 250601 | 250621 | 250619 | 250606 | 250628 | 250613 |

| 3 | 250602 | 250618 | 250622 | 250607 | 250629 | 250614 |

| 6 | 250603 | 250623 | 250624 | 250608 | 250630 | 250615 |

| 9 | 250604 | 250625 | 250617 | 250609 | 250631 | 250616 |

| 15 | 250605 | 250626 | 250627 | 250610 | 250632 | 250633 |

Other Diamond Suspensions Available

Type AP Diamond Suspension

Kemet Diamond suspension AP is a high quality alcohol based polycrystalline diamond suspension. It is ideal for polishing specimens which must not come into contact with water. Available in 500ml bottles (other sizes available upon request)

| 500ml | |

|---|---|

| Micron | Code |

| 1 | 250350 |

| 3 | 250271 |

| 6 | 250272 |

Type WX Diamond Suspension ... A high viscosity liquid diamond suspension!

For most applications where a liquid diamond suspension is required, we would recommend Aquapol-M (manufactured with monocrystalline diamond powder) or Aquapol-P (manufactured with polycrystalline diamond powder).

However, for a certain number of specialised applications, where a more viscous liquid diamond is called for, we have developed a suspension called Type WX.

- WX is highly suitable for the polishing of metallographic samples.

- No agitation is required - the diamond remains in suspension.

- The finely graded diamond powder is uniformly dispersed throughout the Liquid carrier, ensuring the generation of perfect surface finishes.

- Available in Strong or Extra Strong Concentrations.

- Water-soluble - components are easily cleaned.

- Colour coded for ease of identification.

- Suitable for use on all types of Kemet Lapping and Polishing Plates.

- Supplied either in 400g, 425g or in 2500 gram (nett) bottles.

If a lubricating fluid is required, Kemet Type W2 is recommended.

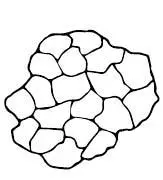

Advantages of Polycrystalline Diamond Suspension

The reason for the superior performance of polycrystalline diamond over monocrystalline results from the structure of the diamond particles. Monocrystalline diamond contains a single crystal structure which has distinct cleavage planes causing the diamond to fracture under stress.

Polycrystalline diamond contains up to several thousand particles less than 0.01 μm in size bonded together in a random structure. When high stress produces microfractures, these are limited to small groups of crystallites on the perimeter. Major cleavage of the diamond cannot occur.

This random structure gives polycrystalline diamond toughness in all directions resulting in less subsurface damage.

Ultra Fast Cutting:

Polycrystalline diamond particles are ultra rough with three times the surface area of Monocrystalline particles.

- More cutting edges

- Faster stock removal rate

- Fewer polishing steps

Finest Surface Finishes:

Polycrystalline diamond particles abrade a workpiece uniformly regardless of orientation. They produce none of the random scratches and microcracking sometimes caused by monocrystalline particles.

- Smoother finishes

- Fewer random scratches

- Less subsurface damage

Fewer Polishing Operations:

Polycrystalline particles are tough and equally strong in all directions. This permits the use of higher unit pressures for lapping and polishing, often reducing the number of steps required.

Maintains Surface Integrity:

Polycrystalline diamond works well with materials that contain various soft / hard / brittle domains such as complex cermets, ceramics and metallographic or petrographic specimens. Polycrystalline diamond preserves the integrity of the surface by not plucking out the brittle areas or aggressively abrading non homogeneous areas.

Blocky Shape with Self Sharpening Particles:

The polycrystalline structure lends itself to the creation of particles that are blocky in shape. As tiny monocrystallites break off, they reveal more equally rough sharp monocrystallites with equally effective multifaceted cutting edges. Blocky mass and shape are preserved.

Faster and Smoother:

Even under low pressure loading of parts, the many small crystallite groups that contact the workpiece achieve extremely high unit pressures which remove material from the surface in small bites. The net effect is both faster stock removal and a smoother polished surface.

Applications

Kemet polycrystalline Diamond Products are particularly recommended for the following applications:

- Sapphire – lapping and polishing of sapphire wafers

- Ceramic products including hip joints and other technical ceramic products where a high quality finish is required

- Fibre optics – in particular for communications terminations

- Metallographic and petrographic applications for polishing sintered materials – for example tungsten carbide and ceramics

- Readrite heads for Disc drives and magnetic recording heads

Kemet Polycrystalline Diamond Products can be tailormade to suit a particular application. Contact Kemet for further information and advice.