CNC Deburring Brushes for after Face-Milling, End-Milling and Drilling. Cutter Mark Removal and Surface Polishing

Overwhelming grinding power, Consistent cutting performance, No deformation XEBEC Brush uses unique abrasive ceramic fiber material instead of abrasive grain. One bristle consists of 1,000 ceramic fibers that work as cutting edges. XEBEC Brush provides outstanding grinding ability to complete CNC deburring and polishing in your CNC machine.

The XEBEC Brush™ uses abrasive ceramic fiber material instead of abrasive grain. One single bristle consists of 500 -1,000 ceramic fibers that works as cutting edges, providing excellent cutting ability.

The XEBEC ceramic fiber has 3 features that enable CNC deburring & polishing:

- Overwhelming Grinding Power

- Uniquely developed ceramic fibers are the abrasives and its fiber content ratio is over 80%. Cutting edges that are made up from the tip of each fiber bristle create overwhelming grinding power. Has 60 times higher grinding power compared with nylon brushes and steadily removes burrs.

- Consistent Cutting Performance

- Due to the structure of XEBEC ceramic fiber, new cutting edges are always exposed. The brush maintains consistent cutting performance to the end, enabling CNC deburring and polishing,

- No Deformation

- Maintains its straight shape and does not spread out like a toothbrush even after repeated use. Thus, it is ideal for CNC deburring and polishing in mass production line.

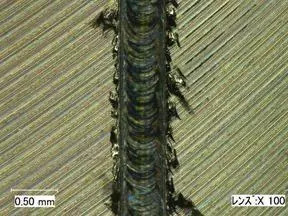

XEBEC Brush™ Surface

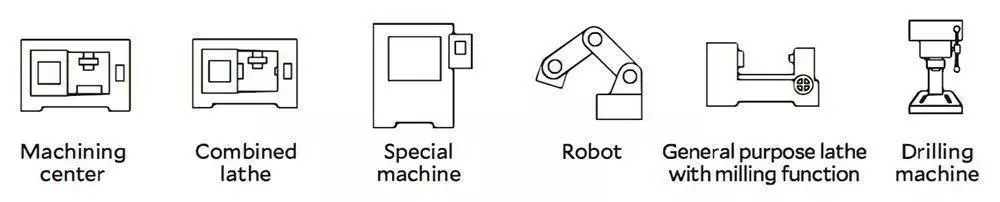

Applicable equipment

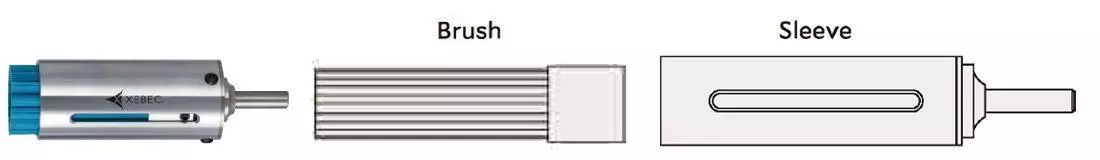

Tool composition

Brush and Sleeve are separate items. Assemble Brush and Sleeve before use.

Brush

| Brush (Color) | Product code | Brush diameter (mm) | Bristle length (l) (mm) | Matching Sleeve |

|---|---|---|---|---|

| A13 (Pink) | A13-CB06M | 6 | 30 | S06M |

| A13-CB15M | 15 | 50 | S15M-P | |

| A11 (Red) | A11-CB06M | 6 | 30 | S06M |

| A11-CB15M | 15 | 50 | S15M-P | |

| A11-CB25M | 25 | 75 | S25M | |

| A11-CB40M | 40 | 75 | S40M-SD10 | |

| A11-CB60M | 60 | 75 | S60M | |

| A11-CB100M | 100 | 75 | S100M | |

| A21 (White) | A21-CB06M | 6 | 30 | S06M |

| A21-CB15M | 15 | 50 | S15M-P | |

| A21-CB25M | 25 | 75 | S25M | |

| A21-CB40M | 40 | 75 | S40M-SD10 | |

| A21-CB60M | 60 | 75 | S60M | |

| A21-CB100M | 100 | 75 | S100M | |

| A32 (Blue) | A32-CB06M | 6 | 30 | S06M |

| A32-CB15M | 15 | 50 | S15M-P | |

| A32-CB25M | 25 | 75 | S25M | |

| A32-CB40M | 40 | 75 | S40M-SD10 | |

| A32-CB60M | 60 | 75 | S60M | |

| A32-CB100M | 100 | 75 | S100M |

Sleeve

| Product code | Brush diameter (mm) | External diameter (Dc) (mm) | Shank diamter (Ds) (mm) | Overall length (L) (mm) | Shank length (ls) (mm) | Matching Brush |

|---|---|---|---|---|---|---|

| S06M | 6 | 10 | 6 | 70 | 29 | A13/A11/A21/A32-CB06M |

| S15M-P | 15 | 18.5 | 6 | 90 | 29 | A13/A11/A21/A32-C815M |

| S25M | 25 | 30 | 8 | 140 | 30 | A11/A21/A32-CB25M |

| S40M-SD10 | 40 | 45 | 10 | 140 | 30 | A11/A21/A32-CB40M |

| S60M | 60 | 65 | 12 | 150 | 35 | A11/A21/A32-CB60M |

| S100M | 100 | 110 | 16 | 162 | 40 | A11/A21/A32-CB100M |

Which Brush do I need?

Which brush for Deburring?

| Workpiece material | Deburring Plastic or Resin | Deburring Copper or Brass | ||

|---|---|---|---|---|

| Deburring Aluminium | ||||

| Deburring General Steel | ||||

| Deburring Stainless Steel | ||||

| Deburring Heat-resistant Steel | ||||

| Deburring Cast-iron | ||||

| Deburring Hard to cut material | ||||

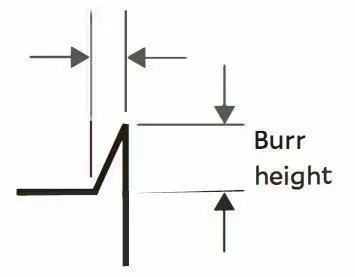

| Thichness of burrs | Micro fine burrs | |||

| Burr root thickness ( < 0.1mm) | ||||

| Burr root thickness (0.1 - 0.2mm) | ||||

| Brush | A13 (pink) | A11 (red) | A21 (White) | A32 (Blue) |

Which brush for Cutter Mark removal?

| Workpiece material | Cutter Mark removal on Copper or Brass | |||

|---|---|---|---|---|

| Cutter Mark removal on Aluminium | ||||

| Cutter Mark removal on General Steel | ||||

| Cutter Mark removal on Stainless Steel | ||||

| Cutter Mark removal on Heat-resistant Steel | ||||

| Cutter Mark removal on Cast-iron | ||||

| Cutter Mark removal on Plastic and Hard to cut material | ||||

| Achievable Surface roughness | < Ra 0.1 µm | |||

| Ra 0.1 µm > | ||||

| Brush | A13 (pink) | A11 (red) | A21 (White) | A32 (Blue) |

XEBEC Brush ™ Surface Extra-Large

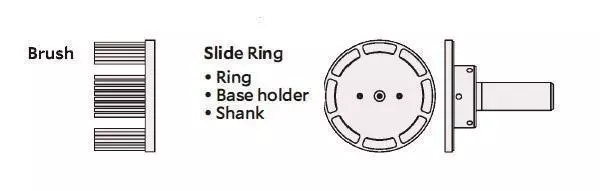

Tool composition

Brush and Slide Ring are separate items. Assemble Brush to Slide Ring before use.

Applicable equipment

Brush

| Brush (Color) | Product code | Brush diameter (mm) | Bristle length (l) (mm) | Matching Slide Ring |

|---|---|---|---|---|

| A11 (Red) | A11-CB125M | 125 | 75 | SR125M |

| A11-CB165M | 165 | 75 | SR165M | |

| A11-CB200M | 200 | 75 | SR200M | |

| A21 (White) | A21-CB125M | 125 | 75 | SR125M |

| A21-CB165M | 165 | 75 | SR165M | |

| A21-CB200M | 200 | 75 | SR200M | |

| A32 (Blue) | A32-CB125M | 125 | 75 | SR125M |

| A32-CB165M | 165 | 75 | SR165M | |

| A32-CB200M | 200 | 75 | SR200M |

Slide Ring

| Product code | Brush diameter (mm) | Outer diameter (Dc) (mm) | Shank diameter (mm) | Overall length (L) (mm) |

|---|---|---|---|---|

| SR125M | 125 | 135 | 25 | 187 |

| SR165M | cp165 | cp176 | cp25 | 187 |

| SR200M | 200 | 211 | 25 | 187 |

Case Study: Precision / Deburring of edge

Material: Steel

Pre-processing: End milling

Description: Making a slot with Ø0.5mm end milling process

Deburring Parameters:

Tool Used: A13-CB15M(XEBEC Cutting Fiber)

Revolutions: 3000min-1

Feed: 2000mm/min

Depth of Cut: 1.0mm

Before Deburring of Edge

After Deburring of Edge

Case Study: Deburring of hole

Category: Electronic part

Pre-processing: Drilling

Description: Remaining burrs on 1.2mm dia. of 7370 holes

Deburring Parameters:

Tool Used: A11-CB15M(XEBEC Cutting Fiber)

Revolutions: 3800rpm

Feed: 350mm/min

Depth of Cut: 0.2mm

Process time:15 min

Before Xebec - Tool used: Impregnated nylon brush. Manual processing required 12 hours for completion

After Xebec - Only took 15 min. of processing for complete deburring Shorten by1/48

Before Deburring of Hole

After Deburring of Hole