Plate Grooving & Facing Machine

The KEMET 15 Precision Diamond Flat Lapping and Polishing Machine, a floor-standing unit equipped with cutting-edge features. This advanced machine is specifically designed for precision lapping and polishing tasks, catering to Kemet Compositae Plates. With its robust metal construction, the KEMET 15 ensures stability and durability during operation. The adjustable worktable allows for precise positioning, while the HMI/PLC control system provides seamless control and convenient programme storage.

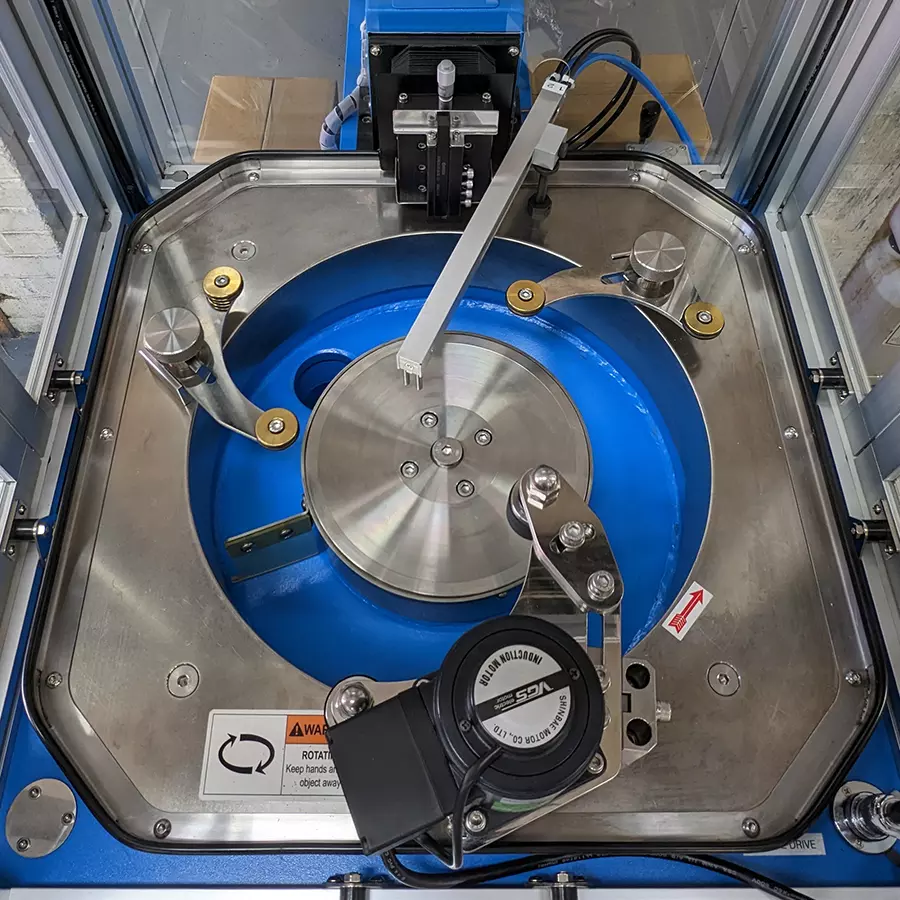

The integrated Plate Grooving Unit of the machine allows for the creation of grooves on lapping plates, improving material removal efficiency during the lapping process. With the Lapping Plate Facing capability, the machine ensures that plates are perfectly flat and smooth, resulting in optimal performance and precision. The KEMET 15 consistently delivers high-precision, optically flat surfaces with an exceptional finish, meeting even the most demanding requirements. Its Electronic Dispensing System accurately metres diamond abrasive onto the lapping plates, reducing costs and minimising waste, thus enhancing efficiency. Moreover, the KEMET 15 offers adaptability by easily customising itself for specific lapping applications, providing flexibility and versatility.

Furthermore, the KEMET 15 offers various optional add-ons to enhance its performance and versatility. The Positive Drives Motor Unit, featuring a Yoke Roller, ensures smooth and efficient operation. The Automatic Liquid Diamond Dispenser & Stirrer enables accurate and controlled distribution of diamond abrasive onto the lapping plates. For added safety, the Machine Protective Cover is available. Additionally, the Water Cooled Lapping Plate System & Chiller maintains ideal operating temperatures for consistent performance.

The facing feature of the machine ensures the lapping plate's surface is flawlessly flat and smooth. Over time, lapping plates can develop imperfections or wear due to repeated use. By facing the plate, any irregularities or roughness on its surface are eliminated, restoring it to an optimal condition. This process is vital for maintaining the plate's accuracy and consistency, directly influencing the quality of lapping and polishing results.

The grooving capability of the machine allows for the creation of grooves on the lapping plate's surface. These grooves play a crucial role in the lapping process as they facilitate even distribution of the abrasive slurry or paste used for material removal. Acting as channels, the grooves enable efficient circulation and controlled distribution of the abrasive, resulting in uniform and precise material removal across the workpiece. This ensures consistent and accurate lapping results.

Combining facing and grooving functionalities into a single machine, lapping plate facing and grooving machines provide a comprehensive solution for maintaining and optimising the performance of lapping plates. They enable users to achieve flat, smooth, and properly grooved lapping surfaces, guaranteeing the highest level of precision and quality in lapping and polishing applications.

| Specification | Kemet 15 Plate Facing & Grooving Machine |

|---|---|

| Diameter Of Lapping Plate (mm) | 380mm |

| Lap Plate Speed | 0 ~ 120RPM |

| No. Of Conditioning Rings | 3 |

| Conditioning Rings Inside Diameter | 140mm |

| Max. Diameter Of Workpiece | <140mm |

| Main Drive Motor | 0.75 HP |

| Electrical Supply | 415V 3Ph 50Hz |

| Machine Size (mm) | 1358 x 735 x 2000 H |

| Nett Weight (Approx.) | 400 Kgs |