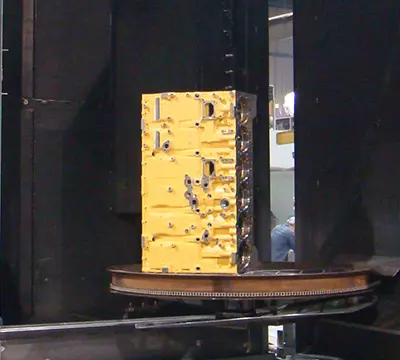

Large & Heavy Duty Parts Cleaning (Industrial, Aircraft, Locomotive, Mining)

Heavy-duty aqueous parts washers and cleaning systems that meet the tough demands of rebuilding applications and manufacturing of heavy machinery, mining, and military vehicle components. These automatic systems are used to remove oil, grease, carbon, dirt, and machining debris from parts such as engine blocks and components. Kemet offers complete solutions, from concept to turnkey installation, custom-engineered to meet your exact production rates and cleanliness specifications.

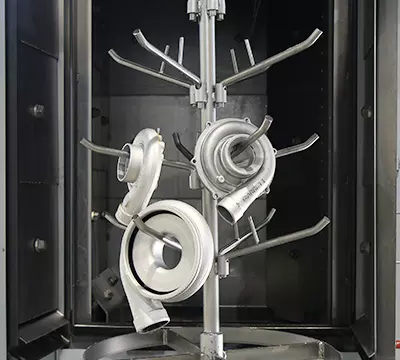

Aircraft & Aerospace Maintenance, Repair and Overhaul (MRO) Cleaning

Whether you manufacture aircraft engines components or provide maintenance, repair and overhaul (MRO) services, we offer a wide selection of aqueous, single- or multi-stage parts washer models to meet your parts cleaning needs. By integrating everything from automated parts handling and DI (deionized) water production to wastewater treatment, these industrial systems are designed to deliver high quality and repeatable cleaning results while reducing chemical and labor costs. Kemet supply you with tailored solutions, from design concept to turnkey installation, to degrease, clean and dry your aircraft components.

The aerospace industry requires reliable parts cleaning technology. Kemet supplies automatic aqueous parts washer to clean and flush aircraft tubes in a manufacturing environment and remove rubber residues, dirt and brake dust from wheel hubs prior to their inspection or overhaul.

Ex-Demo Machine for sale - Parts Washing Machine

This system is perfectly suited for various industries, such as transportation, metalworking, printing, and reconditioning. It provides notable benefits by leveraging part movement within the liquid, which significantly reduces washing time and improves cleaning efficiency. Crucially, this increase in efficiency does not compromise the lifespan of the cleaning media. The system’s agitation machinery is specifically designed to eliminate oils, metal chips, and particulates from a wide range of components. It achieves this using water-based detergents and environmentally friendly solvent chemistries, ensuring both effective and eco-conscious cleaning. Additionally, all operations are precisely controlled by an advanced PLC (Programmable Logic Controller) unit, which guarantees reliable, automated system management. This control system enhances operational consistency and reduces the risk of errors, making the system highly efficient and easy to use.

Machine Cost: AU$ 35,000 + Shipping

| PAW1000 Technical Specification | |

|---|---|

| Loading Capacity | 1.000 Kg |

| Platform | 1300x900 mm. |

| Inside Tank Material | AISI 316 Stainless Steel |

| Solution Volume | 1900 lt. |

| Solution Depth | 1100 mm. |

| Electric | 380 V/50 Hz/3 Ph |

| Control | PLC |

| Filter | 2 Hp Circulation Pump,500 Micron Filter |

| Platform Movement | By Pneumatic Pistons |

| Platform Movement | 700 mm. (Depends On The Work Pieces Height) |

| Cycle | 0-40 Per Minute Short And Long Stroke (Adjustable) |

| Temperature Ranges | 20-90 °C |

| Temperature Control | Digital |

| Control Voltage | 24 Volt Dc. |

| Electric Heating System | 48 kW; 380 V/3 Phase/50 Hz. |

| Required Air Pressure | 6-7 Bar |

| Agitation | Fast Or Slow Agitation Speed |

| Cover | Lifting And Closing By Pneumatic Pistons |