Cleaning of Aerospace & Aircraft Parts

Offering a wide selection of automatic aqueous parts washers for degreasing, cleaning and removing debris from aircraft & aerospace parts

Automatic Aircraft Tube Cleaning System

The Automatic Aircraft Tube Cleaning System is a sophisticated piece of equipment designed to thoroughly cleanse stainless-steel, aluminum, and titanium aircraft tubes that have undergone cutting and shaping processes. These tubes are vital components used in pneumatic, hydraulic, fuel, and oxygen systems and must be impeccably cleaned before inspection. This state-of-the-art machine boasts the capability to clean up to ten parts every hour, ensuring that they are visually devoid of any residual coolants or forming lubricants.

Notably, this system prioritizes environmental responsibility. It eschews the use of solvents altogether and relies exclusively on biodegradable commercial detergents. Employing a re-circulating principle, it efficiently recycles water-based cleaning solutions, thereby conserving energy, detergent, and water resources. The power spray principle employed by this system yields both high-quality and high-speed cleaning results. The chemical cost is notably low, with only 3 to 5% detergent mixed in water, while the energy cost is kept to a minimum through the implementation of fully insulated spray cabinets and tanks with programmable heating systems. Importantly, it poses no health hazards to workers, ensuring their safety and well-being.

Constructed with SS 304L materials in wetted parts, this system is engineered for durability and reliability. Furthermore, it offers the flexibility of pre-programming up to ten cleaning sequences into its PLC (Programmable Logic Controller), streamlining operations. The presence of three flushing stations, with a typical cycle time of 15 minutes, further enhances efficiency.

Compared to immersion systems, this machine is a more efficient and faster production solution, reducing energy costs thanks to its smaller tank volumes. It operates seamlessly within a Just-in-Time (JIT) environment, tailoring tube production to meet spare parts demand ranging from ¼ inch to 3 inches in diameter. This optimized approach to production significantly reduces inventory and enhances overall efficiency.

To ensure thorough cleaning, the machine employs full-cone spray nozzles strategically positioned above the tubes, resulting in improved outer diameter (OD) cleaning results. In conclusion, the Automatic Aircraft Tube Cleaning System stands as a testament to cutting-edge technology, environmental consciousness, and efficiency in the aerospace industry, setting new standards for tube cleaning excellence.

Conveyor Washer for Aircraft & Aerospace Parts

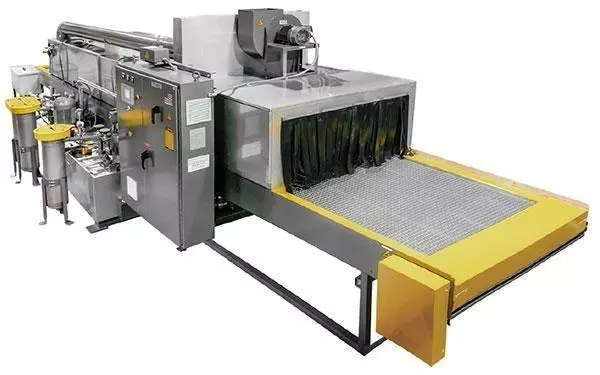

Experience the pinnacle of cleaning technology with the TYPHOON® MB-S, a robust and innovative belt conveyor aqueous cleaning system that stands as the most comprehensive offering in its class. Crafted with durability and advanced cleaning capabilities in mind, this system is a crucial component in modern manufacturing processes, ensuring that freshly manufactured components are impeccably cleaned and primed for inspection, assembly, and packaging.

What sets the TYPHOON® MB-S apart is not just its cleaning prowess but its adaptability. Built upon a foundation of versatile pre-engineered modular platforms, we have the agility to deliver a tailor-made system tailored to your specific requirements with unmatched speed—making us the frontrunner in the industry.

Key Features:

- Easily accessible stainless-steel filters facilitate solution return flow.

- Hinged covers on the solution tank grant effortless access.

- Incoloy-sheathed electric immersion heaters ensure efficient heating.

- Low solution level control safeguards the heating system.

- V-jet spray nozzles, mounted on elbows, offer adjustability for precise cleaning.

- Automatic solution level control, featuring stainless-steel float balls.

- Low solution level cut-out switch for heating system protection.

- Direct-coupled centrifugal pump assembly with a submerged wet end.

- Pump can be removed for servicing without draining the tank.

- Variable-speed AC conveyor drive gearmotor for flexibility.

- Digital temperature controllers provide accurate heat management.

- Comprehensive industrial control package with a 7-day programmable heating timer.

- All moving parts are safeguarded with protective guards.

- Enjoy 24/7 PROCECO customer service support.

- A vast inventory of replacement parts is readily available.

Versatile Options:

- Choice of 2-ft, 4-ft, and 8-ft spray sections.

- Additional solution stages for enhanced cleaning.

- Stainless-steel construction for added durability.

- Gas solution heating system for increased efficiency.

- Thermal tank insulation for improved heat retention.

- Solution filtration to maintain cleanliness.

- Oil separation systems for enhanced performance.

- Counterflow solution level make-up for optimal operation.

- High-pressure regenerative blow-off system for thorough drying.

- Convection dryers to expedite the drying process.

- Part cooling tunnels to ensure components are cooled efficiently.

- Drain valves for easy maintenance.

- Exhaust demister for improved air quality.

- Custom guide rails to match your specific needs.

- Indexing conveyor for precise robot loading.

- Extended load/unload sections for seamless operation.

- Part detection for automatic loading/unloading.

- Custom part fixtures to accommodate various components.

- Custom paint colors to align with your branding.

- Marine-type tank maintenance access doors for convenience.

- And an array of additional options to meet your unique requirements.

Elevate your cleaning process to new heights with the TYPHOON® MB-S Conveyor Washer, the ultimate choice for aerospace and aircraft part cleaning and preparation.

Cleaning Aerospace Parts - Case Study

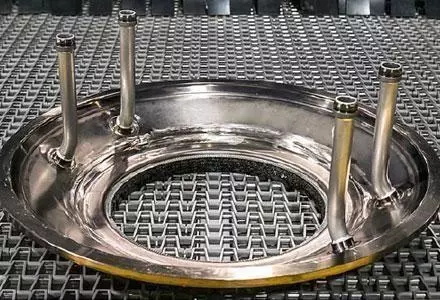

Cleanliness Specification: Visually free of solid and liquid contaminants

Dryness: Isolated solution droplets on parts surface

Exit Temperature: Ambient +/- 2˚F

Customer: Leading aircraft engine manufacturer

Workpiece; Aerospace components

Application: Cleaning during manufacturing process

Production: 12 parts per hour

Cleanliness Visually free of solid and liquid contaminants

Before cleaning Aerospace part

After cleaning Aerospace part

Inline Conveyor Cleaning System

The Typhoon-MB, an inline conveyor cleaning system specifically designed for aircraft parts. This system combines rugged construction with state-of-the-art cleaning technology, making it the most comprehensive spray belt aqueous cleaning system available on the market today.

The Typhoon-MB boasts a range of standard features that enhance its efficiency and effectiveness. It includes chip baskets strategically positioned below a hinged tank lid, ensuring efficient debris management. The system utilizes Incoloy sheathed electric immersion heaters to provide reliable and efficient heating for the cleaning process. A low-level float switch is integrated to protect the heating system, ensuring its optimal performance.

Furthermore, the Typhoon-MB incorporates quick disconnect spray risers, gull wing doors equipped with safety limit switches, and an automatic solution level control system with stainless steel floats. The system also features a seal-less vertical pump with a submerged wet end, a sloped tank bottom, and a baffled tank design for optimal solution re-circulation. Notably, the pump can be removed for servicing without the need to drain the tank, and the pump motor can be removed without detaching the pump itself.

In terms of operation, the Typhoon-MB offers a variable speed DC conveyor drive, digital indicating temperature controllers, and illuminated push-pull buttons for main functions. Safety is a top priority, with an emergency stop button located at both the load/unload ends and the main control panel. The system also includes a 7-day programmable heating timer and high-efficiency motors that meet NEMA design B standards, along with Allen Bradley I.E.C. standard motor controls.

For customization and additional features, the Typhoon-MB offers a range of options, such as different spray section lengths (2ft, 4ft, and 8ft), additional solution stages, stainless steel construction, and various heating methods (gas/steam/hot water). Tank insulation, solution filtration, oil separation systems, counter-flow make-up, high-pressure regenerative blow-off systems, convection dryers, part cooling tunnels, drain valves, exhaust demisters, custom guide rails, indexing conveyors, extended load/unload sections, power flushing, part detection systems, custom part fixtures, custom paint options, and extreme-duty models are also available to meet specific cleaning requirements.