Monochromatic Light Source

Produces clear flatness readings when used with Kemet Optical Flats. The compact designed Light is easily transportable and uses a sodium long-life sodium light source. Supplied with a flatness reading interpretation chart.

- Detachable power lead with on / off switch at the side

- 110V model (50 or 60 Hz) with USA plug – Kemet Code 363044

- Supplied with compliance certificate and instructions

- CE marked

Our sodium bulbs have a wavelength of 590nm.

Large Monochromatic Light

Kemet large Monochromatic Light units, designed for use with optical flats up to 500mm in diameter, allows for precise measurement of surface flatness to within millionths of an inch. Utilising a sodium long-life light tube, these self-contained units provide a glare-free light source. When used in conjunction with Optical Flats, contrasting light and dark bands are easily observed on most reflective or semi-reflective surfaces. Dimensions: H 460mm x W 550mm x D 400mm, work area depth 280mm

- 110V model (50 or 60 Hz) with USA plug - Kemet Code 363044A

- Supplied with compliance certificate and instructions

- CE marked

Flatness Inspection Using a Kemet Monochromatic Light

1. It is critical that both the component and optical flat are perfectly clean before inspection. Any amount of contamination, regardless how small, will affect the measurement. 1 sodium light band is equal to 0.29 microns, so any particles or smears on the surface of either the component or the optical flat will affect the measurement.

This illustration shows how a human hair compares in size to a 1 micron particle. You will not see particles that are 1 micron in size, but if present, these can affect the flatness reading by as much as 3 light bands. This highlights the need for perfectly clean components and optical flats. When cleaning the optical flats, use a lens grade cleaning tissue and either Isopropyl Alcohol or Kemet CO42 cleaning fluid. Harsh tissues will cause scratches on the optical flat.

2. The Kemet Monochromatic Light should be turned on at the start of every shift. The sodium bulb will take up to 15 minutes before it is ready to be used for inspection. The light should be orange in color when ready.

3. Position the part so that it is under the monochromatic light ensuring that the entire surface to be measured is within range of the light.

4. Place the optical flat over the area that is to be measured. Do not slide the optical flat as this will generate scratches. Apply light finger pressure to the optical flat to remove as much air as possible from between the component and the optical flat. This will usually make the light bands easier to read.

The black line on the monochromatic light lamp cover should be reflected on the surface of the optical flat. The number of light bands that this black line passes through will give the flatness reading if the bands are straight or curved.

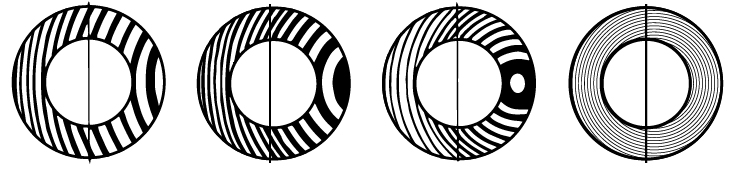

| Surface geometry | 1 Light band 0.00029mm | 2 Light bands 0.00058mm | 3 Light bands 0.00087mm | 9 Light bands 0.00261mm | |

|---|---|---|---|---|---|

Convex or ConcaveSurface parallel to flatSymmetrical Pattern |  |  | |||

ConvexWith concave surface band will curve in opposite directionNon-Symmetrical Pattern |  |  | |||

CylindricalConvex or ConcaveSymmetrical Pattern |  |  | |||

Saddle ShapedSymmetrical Pattern |  |  | |||

The chart above shows typical flatness readings. These black lines simulate the black line on the Monochromatic light lamp cover. This is used only when the light band patterns are curved. For other light band patterns refer to the chart above. The same chart is supplied with the Kemet Monochromatic Light.

5. Once the flatness measurement has been completed, lift (do not slide) the optical flat off the component and return it to its protective box.

Replacement Bulbs for Mononlight

Make sure you order the correct replacement bulb!

| Monolight Version | Replacement Bulb | Description | Product Code |

|---|---|---|---|

|  | 35W bulb (32cm) | 362607 |