Diamond Lapping Products

Kemet offer a wide range of standard and special Diamond Products formulated and manufactured in our quality controlled laboratories. Each is a special blend of diamond powder with a specific grading and concentration in a chemical carrier to give the optimum:

- The optimum stock removal and surface finish

- Ease of cleaning

- Temperature resistance

- Lubrication to prevent drying out

Other diamond products available are; Diamond Spray, Diamond Compound Stick and Diamond Gel.

With changing technology, new Kemet Diamond Products are continually being developed to meet specific requirements. These products may well incorporate different types of diamond to suit the application such as synthetic or natural, monocrystalline or polycrystalline powder, suspended in a wide range of chemical carriers. Our laboratories can also help to develop formulations specific to your application.

We use only the best quality virgin Diamond Powder and high purity chemicals in Kemet Diamond Products. Most Kemet products are biodegradable.

- Diamond Grading - The exceptionally close grading standards developed by us exceed many international standards and guarantee Kemet Diamond Products are manufactured to the closest tolerances.

- Quality Control - Microscopic and computer analysis of the Diamond Powder ensures that it is exactly the correct grading and shape to maximize cutting performance.

- Consistency of Performance - Manufactured to ISO 9001:2015 Quality Assurance standards. Our guarantee that the quality will be consistent.

- User Friendly - Manufactured from high purity chemicals - safe to use and friendly to the environment.

Monocrystalline:

This diamond has tough resilient crystal structure that gives sustained cutting power. It is the type of diamond used most commonly in Kemet Diamond Compounds and Slurries.

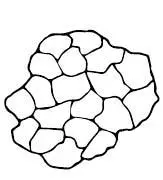

Polycrystalline:

Structure is ‘raspberry-like’, i.e. each particle is in fact a number of very small particles of microcrystallites bonded together. Stock removal and surface finish is better due to the many cutting points of the polycrystalline crystal.