Deburring Systems

High-Speed CNC Hydro-Deburring System

The Accu-Jet® is a CNC controlled, hydro-deburring machine tool designed to flush and deburr precision metal or plastic parts. At the heart of the Accu-Jet® is a four-axis CNC controlled Cartesian gantry robot designed to pick a part from a feed conveyor, flush and deburr the machined surfaces using high-pressure water at high speed, and return the part to an exit conveyor. Cycle times can be greatly reduced with an optional fifth axis, allowing simultaneous processing of paired part features. High-pressure water up to 10,000 psi is recirculated and filtered to provide a closed-loop and environmentally friendly process. The Accu-Jet® is also available with optional feed and exit conveyors, a high-impact air blow-off, and vacuum drying to provide users with a complete integrated solution. Part manufacturers seeking flexibility, reliability and repeatability can rely on the Accu-Jet® to solve their production deburring requirements.

High-pressure water jets are used to effectively deburr and flush away unwanted burrs, chips and debris from narrow cavities, internal intersections, threads, and component edges of complex machined parts. Pressure acts as a means of accelerating the water to supersonic speeds and when water hits the part, it shears, pushes, and erodes away the burrs and removes debris in its path without damaging surface finishes or radius edges. This method is environmentally safe and does not use potentially damaging abrasives or solvents. Depending on the part geometry, a combination of specialized fixed and rotating nozzles are used to direct high-velocity water jets at specific areas or at the overall surface of a workpiece.

Hydro-deburring cannot remove all types of burrs. To test if highpressure deburring is the appropriate deburring method, see if the burr can be removed by pushing it with the lead of a 0.7 mechanical pencil without breaking the lead.

This technology produces consistent repeatable results at high production rates. Designed for total flexibility, this equipment can adapt to a variety of parts and be programmed for an infinite number of configurations.

Complex machined parts made of steel, ductile iron, aluminum and plastic such as fuel-injection components, ABS and traction control valves, transmission parts, pump housings, and pistons.

Precision Deburring

A CNC-controlled, gantry-style Cartesian robot manipulates workpieces precisely in close proximity to high-pressure water jets to effectively remove unwanted burrs, chips, and debris from narrow cavities, threads, and workpiece edges without damaging surface finishes or radius edges.

Ideal for Compact Precision Parts

Kemet can supply custom designed grippers to handle workpieces of up to 20 lbs in weight and 12 inches cubed in size.

Flexible and Reliable

With a CNC programmable robot, replaceable high-pressure deburr bolted tooling, and robot gripper, the Accu-Jet® allows process flexibility by adapting rapidly to various part configurations.

Integrated Part Loading

After passing through an identification station, workpieces are picked up from the feed conveyor by the gantry robot. The workpiece is then transported into the process cabinet for flushing and deburring.

Dual Manifold

An optional servo-controlled D axis can significantly reduce cycle times on workpieces with paired hole patterns. This feature permits paired holes to be flushed and deburred simultaneously, resulting in shorter cycle times.

Indexing Rotary Axis

The rotary indexing R axis changes the part orientation to expose different surfaces to the high-pressure deburring tools.

Rotary Deburring Probe

The rotary horizontal probe effectively deburrs and flushes away chips from threads, narrow cavities, and difficult-to-access intersections; all in one operation.

Advantages

- Integrated parts loading/unloading

- Full four-axis CNC programmable movement

- Easy to adapt to various part configurations

- Designed for larger rotary deburring nozzles

- Bolted deburring tooling: fast, easy & flexible

- Can incorporate up to 12 different water-jet deburring tools

- Few moving parts; designed for reliability

- Process all sides of a part in one setup without regripping

- No tool changer to maintain

- Compact footprint

- Fast cycle time

Machine Specification

| Dimensions | 8'-10" W × 14' L × 11'-8" H |

|---|---|

| Power requirements | 480V/ 3-phase/ 60Hz, 100A |

| Compressed air requirements | 30 cfm @ 90 psi |

| Chilled water requirements | 24 USgal/min @ 40°F |

| Solution tank capacity | 80 USgal |

| Low-pressure pump capacity | 30 USgal/min @ 45 psi, 3 hp, 3600 rpm |

| High-pressure pump capacity | 17 USgal/min @ 5000 psi, 60 hp, 1200 rpm * |

| Solution operating temperature | Ambient to 120°F |

| X Axis Stroke / Repeatability | ± 60 in / 0.004 in (0.1 mm) |

| Y Axis Stroke / Repeatability | ± 24 in / 0.0004 in (0.01 mm) |

| Z Axis Stroke / Repeatability | ± 24 in / 0.0004 in (0.01 mm) |

| Maximum linear spead | 160 feet/min |

| D axis, linear nozzle set | 6" stroke ** |

| Rotary R axis | 360° |

* Higher pressure available, up to 10 000 psi

**Can be customized to adapt to part geometry

Standard Features

- Three linear axes (X-Y- Z) for positioning

- One rotary indexing R axis

- Corrosion-resistant linear modules

- All axes are CNC controlled

- One rotary flushing/deburring nozzle probe (AC-motor driven)

- Can receive up to 12 deburring nozzles of various types and larger rotary deburring nozzles

- Safety guarding on all moving parts

- Stainless-steel 304 construction for components in contact with solution (tank, cleaning cabinet, piping, filters)

- Welded cabinet construction

- Three-stage dirty solution tank weir system

- Stainless-steel 304 cartridge filter with pressure switch for clogged filter alarm

- Stainless-steel 304 vertical-process centrifugal pump (low-pressure feed)

- Triplex plunger pump with stainless-steel fluid end (high-pressure feed)

- Automatic 2 ¼" belt oil skimmer

- Replaceable wear plates inside cabinet

- Large hinged access door on cabinet wall

- Process inspection windows with lighting

- Stainless-steel 304 exhaust (optional demister)

- High-pressure fluid cooling heat exchanger

- Automatic solution level control

- Noise-reduction enclosure system for high-pressure pump

- High-efficiency, low energy consumption motors

- Touchscreen operator interface displays machine status, temperature levels, fault warnings and diagnostics

- Warning horn to alert operator of system faults

- Flanged main disconnect switch

- Pump safety interlock on access doors and bag filters

- Maximum noise level of 82 dBA

- System can be customized and integrated with additional processes

Workpiece Specification

| Working envelope | 24" x 24" x 24" |

|---|---|

| Maximum weight | 20 lbs |

| Maximum dimensions | 12" x 12" x 12" |

| Part materials | Aluminum, Steel, Plastic |

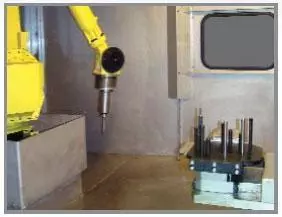

Six-Axis, Robotic Hydro-Deburring System

The RDB-700 is a robotic cleaning and deburring system designed to remove burrs, chips, and non-parent material from medium-sized, complex machined components. Using highpressure rotary water jets, an articulating robot is programmed to deburr all the machined holes, intersections, and difficult-to-access cavities of a workpiece mounted on a fixture. The lance nozzle precisely sprays a pressurized water-based solution to clean, flush, and deburr in a single operation. After cleaning, air is directed through the lance nozzle and the robot again passes through all machined areas, blowing excess solution away from the part.

The RDB-700 is a flexible system that combines reliability, precision, and quality – ideally suited to a machine shop environment.

Precision Deburring

The robot precisely aims the high-pressure water jet lance to effectively remove burrs, chips, and debris from cavities, threaded holes, and edges without damaging surface finishes or radius edges.

Ideal for Medium-Size Parts

Workpieces are loaded on a rotary table with two fixtures designed to process one part while the other is being loaded

Flexible and Reliable

The system features replaceable high-pressure tooling offering flexibility and repeatability by adapting rapidly to various part configurations.

Standard Features

- Robotic high-pressure water jet deburring and air blow-off

- Six-axis, foundry-grade articulating robot

- Stainless-steel construction

- No-tangle system for robot water and air hoses

- Two-position, precision indexing table

- Single load/unload point, ready for automated loading

- Rotary table capable of holding a combined (part + fixture) weight of 600 lbs per position

- Part presence detection at the load/unload point

- Automatic loading/unloading doors

- Solution tank with weir contaminant separation system

- Solution filtration

- Vertical-process centrifugal pump (low-pressure feed)

- Triplex plunger pump (high-pressure feed)

- Programmable logic controller

- Touchscreen interface with machine status, fault warnings, and diagnostics

- Process inspection windows with cabinet lighting

- Full-height, hinged access door on cabinet wall

- Easy-to-read digital pressure and temperature gauges

- Electric immersion heater

- Automatic solution level control system

- Mist collector

- Safety interlocks on access door

- Maximum noise level of 82 dB(A)

Workpiece Specifications

| Working envelope | 42.83 in.² |

|---|---|

| Maximum weight per rotary table position | 600 lbs |

| Part and fixture maximum size* | 14" x 16" x 25" |

| Part materials | Aluminum, Steel, Plastic |

Machine Specifications*

| Dimensions | 10'-3" W × 11'-11" L × 10'-3” H |

|---|---|

| Power requirements | 480V/3-phase/60Hz, 112A |

| Air requirements | 40 cfm @ 60 to 120 psi |

| Clean solution tank capacity | 160 USgal |

| Low-pressure pump capacity | 90 USgal/min @ 60 psi |

| High-pressure pump capacity | 8.6 USgal/min @ 10,000 psi |

| Chilled water required | 24 USgal/min @ 40°F |

| Loading/unloading height | 36” |

| Machine weight with empty solution tank | Approx. 10,000 lbs |

| Robot repeatability** | ± 0.00276 in. (0.07 mm) |

| Robot reach | 53.5 in. (1360 mm) |

| Robot payload | 53.5 in. (1360 mm) |

| Robot payload | 110 lbs |

| Operating temperature | 95 - 105°F |

*Specifications may vary according to machine configuration and options

**May vary according to robot used