Metallography Grinding and Polishing Machines

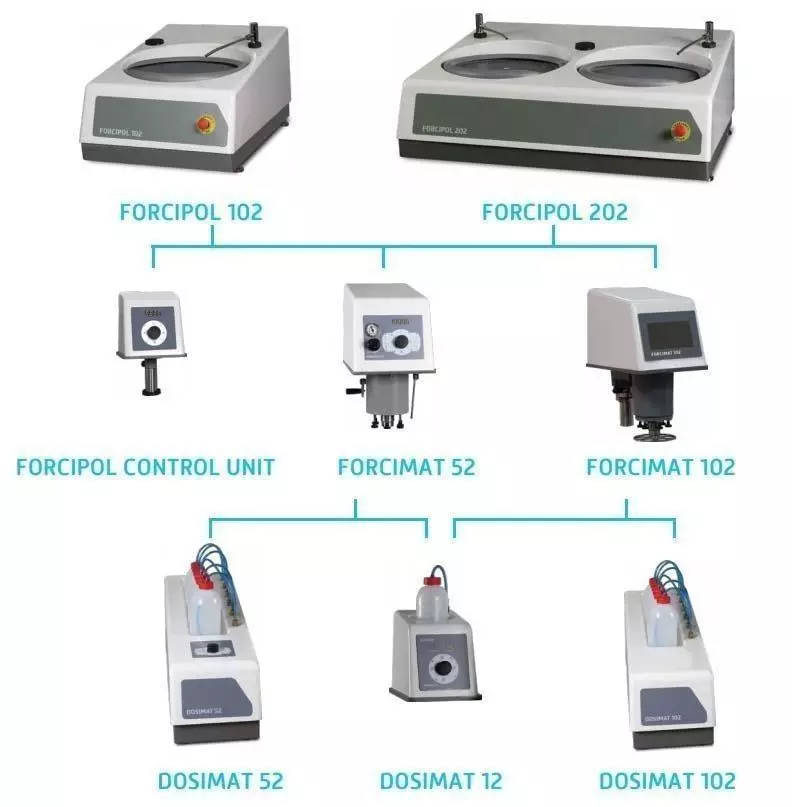

The FORCIPOL Series of grinding and polishing machines offer practical and economical solutions to your metallographic sample preparation needs. FORCIMAT is a microprocessor controlled sample mover designed to be used with FORCIPOL grinder / polishers. It is ideal for medium size labs where consistent result are desired.

All materials testing laboratories in the industry, research or educational field have a demand for sample preparation. Whether your requirements call for individual components or basic sample preparation, FORCIPOL family of instruments will meet your needs. FORCIPOL Series of instruments are available as Single wheel (FORCIPOL 102) and Dual wheel (FORCIPOL 202) Units.

The modern electronics provide a smooth speed variation. The drive elements are fixed on heavy duty aluminium alloy casting. The wheels are mounted on ball bearings allowing the application of high pressures to prepare even large specimens. Ball bearings used provide quite and vibration free operation. Water inlet and flexible water outlets with control valves for wet grinding are standard features.

Both single and double wheel versions are suitable with Ø200, Ø250 and Ø300 mm wheels. The working wheel is powered by a high torque 1.0 HP electric motor with both clockwise and counterclockwise wheel rotation possibility. The state of the art frequency converter allows smooth speed variation (50-600 rpm) of the grinding wheel with soft start and soft stop. Both . This allows the setting of the optimum speed for each individual preparation process. It is perfect choice for laboratories preparing a wide range of different materials from very small to very large.

FORCIPOL instruments can be used for grinding, lapping and polishing with magnetic backed discs and cloths or by quick and simple exchange of wheels. When the number of specimens to be prepared increases, FORCIPOL instruments can be fitted with FORCIMAT automatic head for automation. FORCIMAT automatic head provides high rate sampe preparation and frees the operator from the grinding and polishing procedures.

Manual Operation

FORCIPOL Control Unit

When only manual preparation is required, FORCIPOL Control Unit can be fitted on the FORCIPOL grinder / polisher. If automatic operation is required in the future, one of the FORCIMAT automatic heads can be installed at any time.

The FORCIPOL Control Unit is ergonomically placed on the equipment. Modern touch pad controls with ergonomic turn knob allows fast and easy setting of parameters and increases productivity. Wheel speed, operation time, motor on/off and water on/off functions can be set in seconds. Cooling water is automatically activated and deactivated at the beginning and end of operation. The actual wheel speed and operation time are digitally displayed. All parameters can be changed during operation. The last parameter settings are always retained in the memory. An audible signal notifies the operator when the process is completed.

Automatic Operation

FORCIMAT 52 (Individual Force)

The FORCIMAT 52 Automatic Head is mounted on a rigid hardened post which is fixed to the base of the FORCIPOL grinder/polisher. It can be adapted to all FORCIPOL series grinder/polishers and is easily and rapidly positioned by means of a quick-locking clamping mechanism.

The sample holder can prepare 6 samples simultaneously and it is driven by a 100 Watt DC motor at 50-150 RPM. The pneumatically applied individual force is adjustable between 5 N (1.1 lb.) and 60 N (13.5 lb.) from the front panel and is displayed on a gauge. The housing is made of ABS with a touchpad front panel.

A choice of easily exchangeable sample holders with set of rings from 25 to 50 mm and 1 ” to 2 ” diameter are available for use on the FORCIMAT 52. The samples (1 to 6) are placed in the sample holder. Thanks to quick replacement mechanism, all individual force specimen holders can be removed and inserted on the equipment within seconds.

Modern touch pad controls with ergonomic turn knob allows fast and easy setting of parameters and increases productivity. Sample force, wheel speed, sample holder speed, operation time, motor on/off and water on/off functions can be set in seconds. When the start button is depressed, both the FORCIMAT 52 and FORCIPOL start operating simultaneously. Cooling water is automatically activated and deactivated at the beginning and end of operation. The actual wheel/head speed and operation time are digitally displayed. All parameters can be changed during operation. The last parameter settings are always retained in the memory. Upon completion of the cycle, both instrument stop and an audio signal notifies the operator.

Automatic Disc Cleaning & Drying function can be activated with a single button to obtain perfectly cleaned disc surfaces in seconds. Smart Water Saving feature allows tons of water saving over the years.

When needed, FORCIMAT 52 can work in manual mode to allow prepare specimens by hand.

FORCIMAT 102 (Individual Force + Central Force + Programmable)

FORCIMAT 102 Programmable Automatic Head is coloured HMI touch screen controlled and with the Base Unit, thus creating automatic preparation system. It is used to prepare high volumes of metallographic, ceramic and mineralogical specimens with consistent reproducible quality. The Automatic Head can apply both “Central” and /or “Individual” forces. It can accommodate single samples as well as multi - sample holders thus offering a perfect solution for all levels of sample throughput requirements. The Automatic Head is mounted to a hardened steel post which is affixed to the cast base of the FORCIPOL grinder/polisher. It can be adapted to all FORCIPOL series grinder/polishers and is easily and rapidly positioned by means of a quick-locking clamping mechanism.

The force on the specimen “individual” or “central” is pneumatically controlled by a pressure transducer. The system is enclosed in an ABS housing with touch screen LCD. The FORCIMAT 102 Automatic Head is rapidly positioned via a quick-locking clamping lever. Material Removal Measurement

Optional encoder allows you to measure the amount of material removed from the surface. The desired grinding depth can be set to grind different type of samples and also for applications that need special accuracy.

It is possible to make manual, semi-automatic or programmable automatic configuration for both single and dual wheel grinder / polisher. The Forcipol Series can be upgraded afterwards with a Forcimat Automatic Head and Dosimat Peristaltic Dispenser.

Head Units

| Model | FORCIPOL Control Unit | FORCIMAT 52 | FORCIMAT 102 |

|---|---|---|---|

| Operation | Manual | Semi Automatic | Programmable Automatic |

| Application of Force | - | Individual | Individual + Central |

| Control Panel | Touch Pad Controls | Touch Pad Controls | 7" HMI Touch Screen |

| Program Memory | Last Parameters Retained in Memory | Last Parameters Retained in Memory | 30 Programs |

| Manual Operation Mode | Yes | Yes | Yes |

| Head Motor Power, Watt | - | 100 | 100 |

| Sample Holder Rotation Direction | - | CW | CW |

| Sample Holder Speed (rpm) | - | 50 - 150 | 50 - 150 |

| Individual Force | - | 5-60 N | 5-60 N |

| Central Force | - | - | 30-500 N |

| Grinding Depth Measurement Accurracy | - | - | 10 μm |

| Disc Cleaning & Drying Feature | Yes | Yes | Yes |

| Smart Water Saving Feature | Yes | Yes | Yes |

| Compatible Instruments | FORCIPOL 102/202 | FORCIPOL 102/202 | FORCIPOL 102/202 |

| Compressed Air Requirement | - | 6 Bars | 6 Bars |

| Dimensions, cm | 20 x 20x 39 | 26 x 46 x 54 | 26 x 46 x 54 |

| Weight,kgs | 5 | 16 | 16 |

Dosing Units

| Model | Dosimat 12 | Dosimat 52 | Dosimat 102 |

|---|---|---|---|

| Number of Pumps (Bottles) | 1 | 6 | 6 |

| Control Panel | Touch Pad Controls | Touch Pad Controls | Controllable from LCD Screen of FORCIMAT 102 |

| Program Memory | Last Parameters Retained in Memory | Last Parameters Retained in Memory | 30 Programs |

| Retract Function | Yes | Yes | Yes |

| Pre-Dosing Function | No | No | Yes |

| Compatible Instruments | FORCIMAT 52/102 | FORCIMAT 52 | FORCIMAT 102 |

| Dimensions, WxDxH, (cm) | 14 x 21x 16 | 20 x 74 x 30 | 20 x 74 x 30 |

| Weight, kgs | 5 | 15 | 15 |

Base Units

| Model | Forcipol 102 | Forcipol 202 |

|---|---|---|

| No. Of Stations | 1 | 2 |

| Motor Power, HP | 1 | 1 |

| Disc Speed (rpm) | 50 - 600 | 50 - 600 |

| Disk Diameter, mm | 200 / 250 / 300 | 200 / 250 / 300 |

| Dimensions, cm | 45 x 74 x 34 | 87 x 74 x 34 |

| Weight, kg | 50 | 55 |

| Mains | 230 V, 50/60 Hz, 1-Phase | 230 V, 50/60 Hz, 1-Phase |

DOSIMAT Peristaltic Dispenser

DOSIMAT Peristaltic Dispenser is an optional accessory for the FORCIMAT 52 and FORCIMAT 102 systems. It is an automatic fluid dispensing instrument used in combination to obtain consistent specimens and to save time and consumables. DOSIMAT can feed both diamond suspensions / lubricants and aluminium oxide suspensions. Automatic dosing of consumables is applied precisely for perfect sample surfaces. Efficiency is further increased with high quality peristaltic pumps that guarantee exactly the same dosing every time for automation and control of consumable consumption. The liquid is dosed exactly to where the operator wants it on the polishing cloth. No vaporization or spray mist occurs. It is possible to clean all the tubes with a single button at the end of preparation steps to eliminate the risk of clogged tubes. Three different DOSIMAT Peristaltic Fluid Dispensers are available for FORCIMAT 52 and FORCIMAT 102:

DOSIMAT 12 (With 1 Peristaltic Pump)

DOSIMAT 12 has one peristaltic and non-misting pump for diamond suspensions, alumina suspensions, lubricant or 2 in 1 suspensions and can be matched with Forcimat 52 and Forcimat 102 Automatic Heads. Modern touch pad controls with ergonomic turn knob allows fast and easy setting of dispensing parameters like; frequency, dosing time, etc. parameters and increases productivity. The last parameter settings are always retained in the memory.

DOSIMAT 52 (With 6 Peristaltic Pump)

DOSIMAT 52 has 5 peristaltic pumps for diamond suspensions / lubricant and 1 pump for aluminium oxide suspension or 2 in 1 suspensions and can be matched with Forcimat 52 Automatic Head. Modern touch pad controls with ergonomic turn knob allows fast and easy setting of dispensing parameters like; frequency, dosing time, etc. parameters and increases productivity. The last parameter settings are always retained in the memory.

DOSIMAT 102 (With 6 Peristaltic Pump)

DOSIMAT 102 has 5 peristaltic pumps for diamond suspensions / lubricant and 1 pump for aluminium oxide suspension or 2 in 1 suspensions and can be matched with Forcimat 102 Automatic Head. Dispensing parameters like; frequency, dosing time, fluid selection etc. are controlled through the LCD screen of the FORCIMAT 102 Automatic Head and can be stored in memory.

Grinding and Polishing Accessories

PVC wheel for Grinder/Polishers

Aluminium wheel for Grinder/Polishers

Paper ring for Grinder/Polishers

Splash guard for Grinder/Polishers

31 53 for FORCIPOL 102 & FORCIPOL 202

31 82/83/93 for FORCIMAT

Cover for Grinder/Polishers

31 06 for FORCIPOL 102 & FORCIPOL 202

Special Plexyglass Protection Unit

31 10 for FORCIPOL 102

Air filtering and lubricating unit

GR 0440 for FORCIMAT

DOSIONE Peristaltic Fluid Dispenser

GR 0874 for FORCIMAT

Cabinet for floor model

GR 0830 for FORCIPOL 102

GR 0938 for FORCIPOL 202

ENVIRO Recirculating Filtering System

GR 0865 for FORCIPOL 102/202

Set of insert rings

33 02 for 30 mm

33 03 for 25 mm or 1"

33 04 for 1 1/4"

33 05 for 1 1/2"

Individual Force Specimen Holders

33 31 Individual force specimen holder, Ø145mm, for 6 x Ø25 mm specimens.

33 32 Individual force specimen holder, Ø145mm, for 6 x Ø30 mm specimens.

33 33 Individual force specimen holder, Ø145mm, for 6 x Ø40 mm specimens.

33 34 Individual force specimen holder, Ø145mm, for 3 x Ø50 mm specimens.

33 35 Individual force specimen holder, Ø145mm, for 6 x Ø1" specimens.

33 36 Individual force specimen holder, Ø145mm, for 6 x Ø1 1/4" specimens.

33 37 Individual force specimen holder, Ø145mm, for 6 x Ø1 1/2" specimens.

33 38 Individual force specimen holder, Ø145mm, for 3 x Ø2" specimens.

33 39 Individual force specimen holder, Ø145mm, Blank.

33 02 Set of insert rings for Ø30 mm (to be used with 33 33)

33 03 Set of insert rings for Ø25 mm or Ø1" (to be used with 33 33)

33 04 Set of insert rings for Ø1 1/4" (to be used with 33 33)

Specimen Holders for Central Force Application

46 81 Clamp type specimen holder, Ø130mm, 6 specimens with Ø25 mm.

46 82 Clamp type specimen holder, Ø130mm, 6 specimens with Ø30 mm.

46 83 Clamp type specimen holder, Ø130mm, 4 specimens with Ø40 mm.

46 84 Clamp type specimen holder, Ø130mm, 6 specimens with Ø1"

46 85 Clamp type specimen holder, Ø130mm, 6 specimens with Ø1 1/4"

46 86 Clamp type specimen holder, Ø130mm, 4 specimens with Ø1 1/2"

46 88 Teardrop specimen holder, Ø130 mm, 6 specimens x 10 - 32 mm.

46 89 Teardrop specimen holder, Ø130 mm, 4 specimens x 10 - 42 mm.

46 44 Clamp type specimen holder, Ø130 mm for 4 rectangular specimens 25 X 32 mm.

46 45 Clamp type specimen holder, Ø160 mm for 3 rectangular specimens 40 x 70 mm.

46 91 Clamp type specimen holder, Ø160mm, 10 specimens with Ø25 mm.

46 92 Clamp type specimen holder, Ø160mm, 8 specimens with Ø30 mm.

46 93 Clamp type specimen holder, Ø160mm, 6 specimens with Ø40 mm.

46 94 Clamp type specimen holder, Ø160mm, 4 specimens with Ø50 mm.

46 95 Clamp type specimen holder, Ø160mm, 10 specimens with Ø1"

46 96 Clamp type specimen holder, Ø160mm, 8 specimens with Ø1 1/4"

46 97 Clamp type specimen holder,Ø160mm, 6 specimens with Ø1 1/2"

46 98 Clamp type specimen holder, Ø160mm, 4 specimens with Ø2"

46 39 Clamp type specimen holder, Ø220mm, 3 specimens for irregular shaped samples