Advanced High-Volume Grinding and Polishing Solution

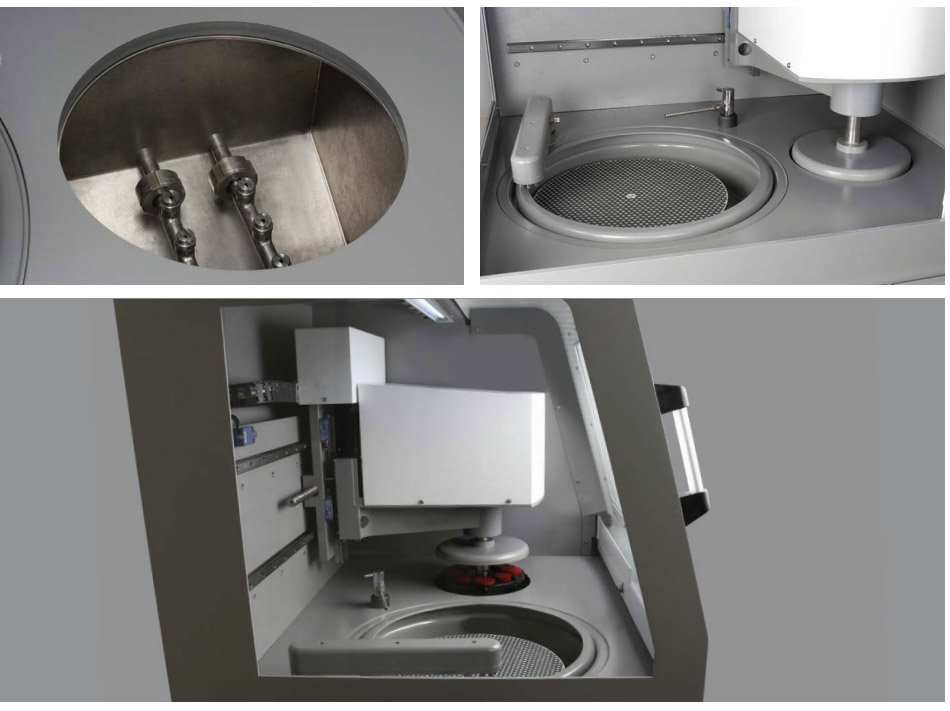

FORCIPOL 352 is expertly designed for the precise grinding and polishing of large specimens or managing a high volume of specimens within specialized holders. It significantly reduces the overall preparation time for high-throughput sample processing. This versatile system is compatible with the FORCIPLAN 352 Planar Grinder, enabling seamless integration to enhance sample throughput. It can easily prepare specimen holders up to 210 mm in diameter, each accommodating 10 specimens, using 350 mm diameter grinding discs.

- Double the Sample Throughput: Achieve up to twice the sample throughput.

- Ideal for Large and High-Volume Specimens: Designed for very large specimens or applications requiring a high specimen count.

- Exceptional Polishing and Planarity: Deliver perfectly polished and planar specimen surfaces.

- Sturdy Steel Construction: Built for heavy-duty operations with robust steel construction.

- Integrated Cleaning and Drying: Prevent contamination with an integrated automatic cleaning and drying station.

- Enhanced Safety: Ensure safe operation within a fully enclosed working area.

FORCIPOL 352 sets a benchmark in high-volume grinding and polishing, offering twice the sample throughput compared to conventional grinding and polishing machines. This versatile system accommodates both Ø350 and Ø300 mm grinding/polishing discs, making it compatible with large specimen holders. Its heavy-duty steel construction, combined with a precise vertical drive, ensures accurate control.

Driven by a high-torque 3 kW motor capable of speeds ranging from 50 to 750 RPM, it enables swift removal of materials from specimen surfaces. Furthermore, the 350 Watt head motor offers bidirectional rotation at speeds between 50 and 200 RPM, ensuring adaptability across diverse materials and applications.

Safety is paramount with FORCIPOL 352, featuring a fully enclosed working area and multiple safety circuits to protect operators and the machine. The system's advanced techniques and software, along with a programmable HMI touch screen interface, enhance productivity, sample consistency, and operator comfort.

Barcode Scanner

An optional Barcode Scanner streamlines the loading of correct parameters for various samples, reducing the risk of loading incorrect programs due to operator error and enhancing overall efficiency.

Grinding and Polishing Parameters

All preparation parameters are conveniently stored in memory under specific program numbers, each corresponding to a material-specific name, such as "Cast Iron," "Bronze," "A-Si Alloy," and more. These parameters include Force, Wheel speed, Head speed, Rotation direction, and Mode of operation (Time or Removal Rate). The user can simply recall a specific program and initiate the process by pressing the "Start" button.

Movable Dosing Arm

FORCIPOL 352 is equipped with a movable dosing arm that evenly applies suspension across the Ø350 mm polishing cloth and uniformly dispenses water onto the grinding disc during use, ensuring optimal cooling of the sample surface. Once the operation is complete, the dosing arm retracts, allowing for easy replacement of the grinding/polishing discs.

Automatic Peristaltic Dosing System

The FORCIPOL 352 integrates an automated peristaltic dosing system featuring six pumps (five for diamond suspensions/lubricants and one for aluminum oxide suspensions). This configuration guarantees uniform specimen quality, enhances efficiency, and reduces consumables consumption. Control over dispensing parameters like frequency and fluid choice is conveniently managed via the FORCIPOL 352's LCD screen.

Fully Automatic Sample Cleaning and Drying Station

FORCIPOL 352 features a fully automated station for cleaning and drying samples, providing pressurized water and ethanol cleaning options, along with rapid drying using filtered air. This station can be programmed for each grinding and polishing stage, eliminating the requirement to remove the sample holder for cleaning and preventing contamination between steps.

FORCI System Combination

The FORCI System combines the FORCIPLAN 352 Planar Grinder and the FORCIPOL 352 Grinding & Polishing Machine, both utilizing Ø350 mm grinding & polishing discs. This combination accommodates up to Ø210 mm sample holders and provides 1.5X to 2X more sample capacity, along with a 10X faster material removal rate with the FORCIPLAN 352 Planar Grinder.

| Model | FORCIPOL 352 |

|---|---|

| Grinding/Polishing Station | Standard |

| Automatic Sample Cleaning & Drying Station | Standard |

| Automatic Peristaltic Dosing Unit | Standard |

| Grinding/Polishing Motor Power (S1) | 3 kW |

| Grinding/Polishing Disc Speed | 50-750 RPM |

| Grinding/Polishing Disc Rotation Direction | CW |

| Grinding/Polishing Disc Diameter | Ø350/300 mm |

| Grinding/Polishing Disc Cleaning & Drying | Automatic |

| Automatic Head Motor Power | 350 Watt |

| Automatic Head Motor Speed | 50-200 RPM |

| Automatic Head Motor Rotation Direction | CW/CCW |

| Grinding Depth Measurement | Standard |

| Grinding Depth Range | 0 - 3 mm |

| Sample Holder Type | Central Force |

| Sample Holder Diameter | Ø210/160 mm |

| Central Pressure Force | 30 - 750 N |

| Sample Cleaning | Pressurized Water + Ethanol |

| Sample Drying | Filtered Pressurized Air Drier |

| Automatic Peristaltic Dosing Unit | Standard with 6 Individual Pumps |

| Magnetic Stirrers | Standard |

| HMI Touch Screen | 7" Colored Touch Screen |

| Program Memory | 35 Programs |

| Dimensions, WxDxH | 1310x840x1600h mm |

| Weight | 700 kgs |

| Mains | 400 V, 3 phase, 50/60 Hz. |